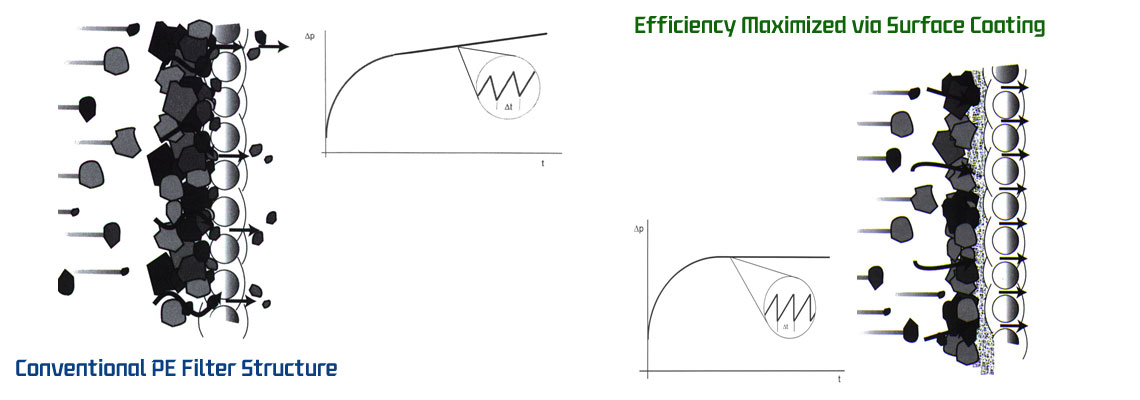

☞ PE filters are inexpensive but have poor chemical resistance. After replacement, pressure drop rises quickly, increasing power consumption. Repeated shrinkage and expansion during cleaning damage the fabric and shorten its lifespan.

☞ Membrane filters offer good chemical properties, but shrinkage and expansion during cleaning can cause delamination or cracking, reducing their lifespan.

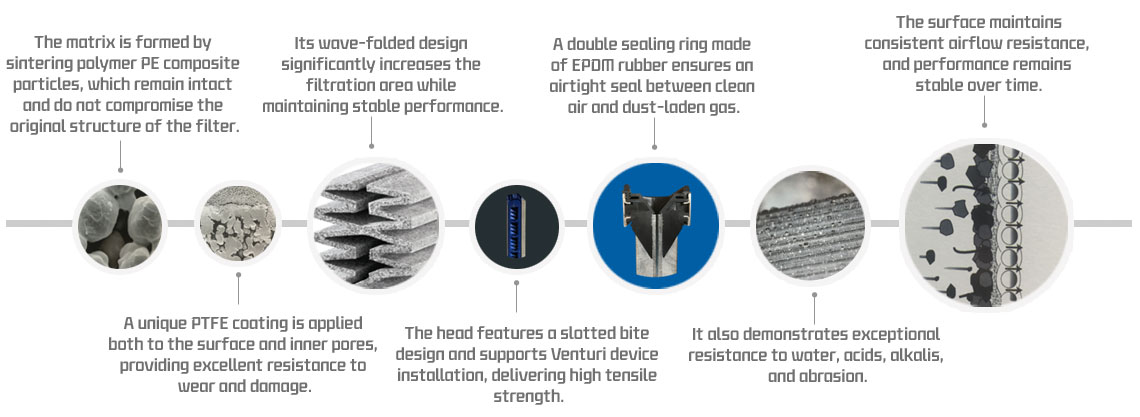

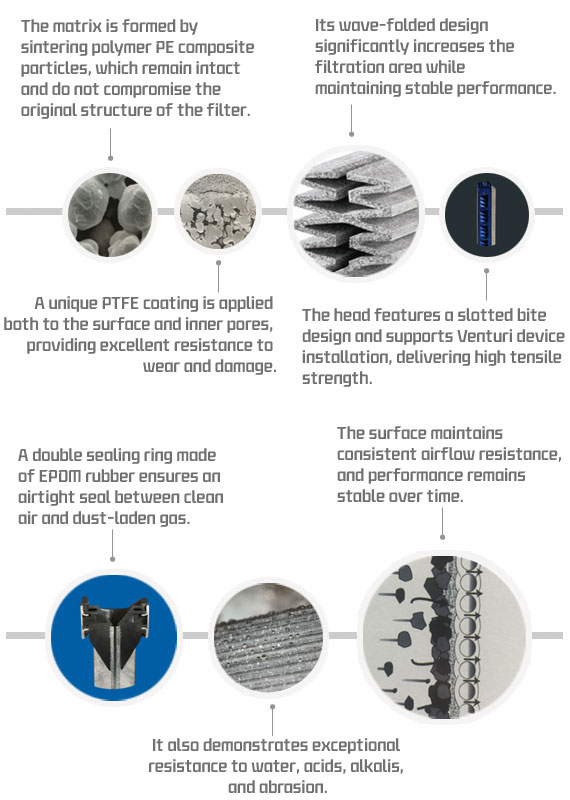

☞ Sintered filters are more expensive, but their rigid structure prevents shrinkage or expansion during cleaning, maintaining consistent performance and extending service life.

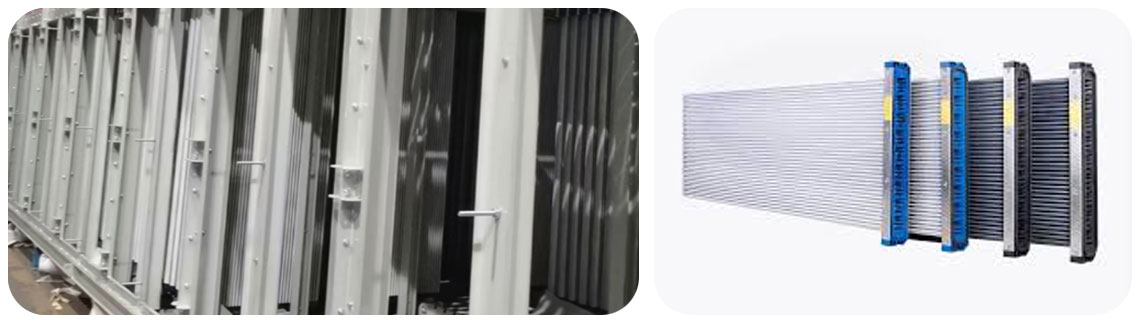

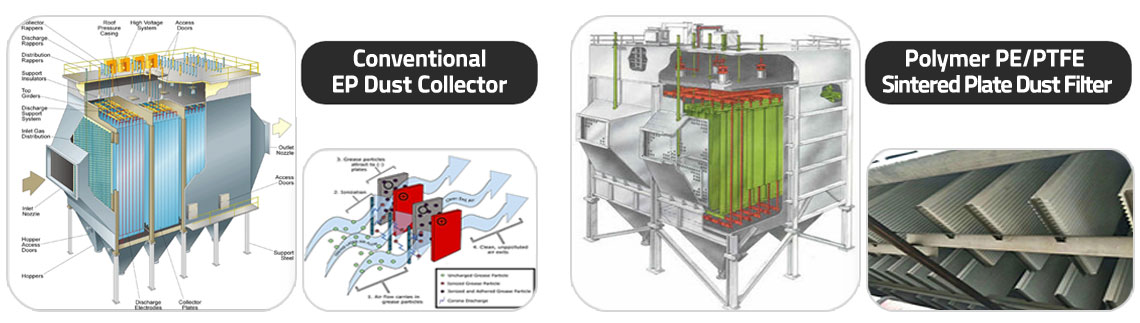

Since no cages are needed, there is no risk of bag damage from friction—either between bags or between the bag and cage, which extends lifespan and avoids equipment shutdowns due to pressure surges.

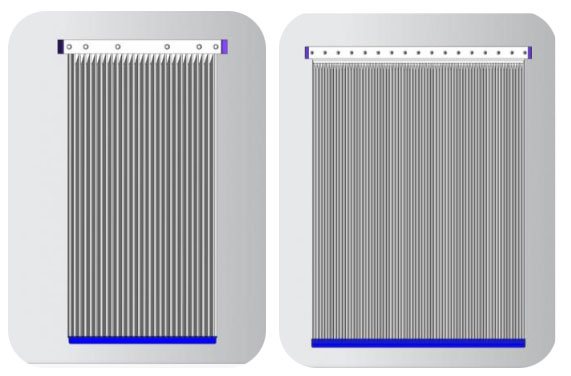

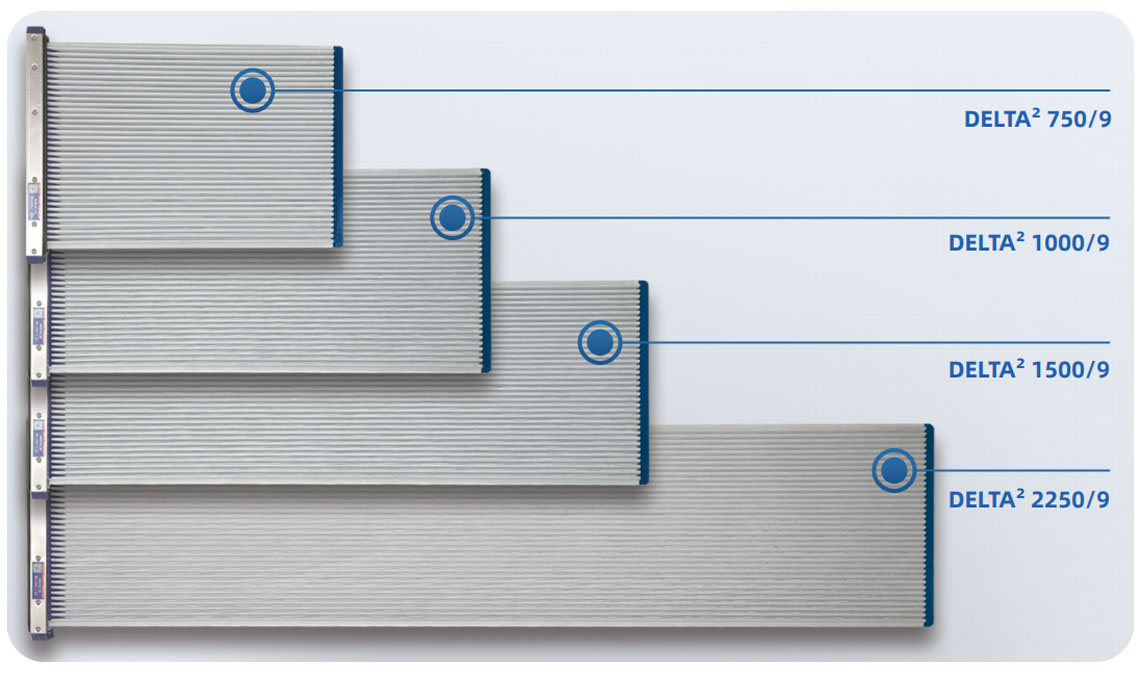

Sintered plate filters come in 8 models and can be applied according to different working conditions.

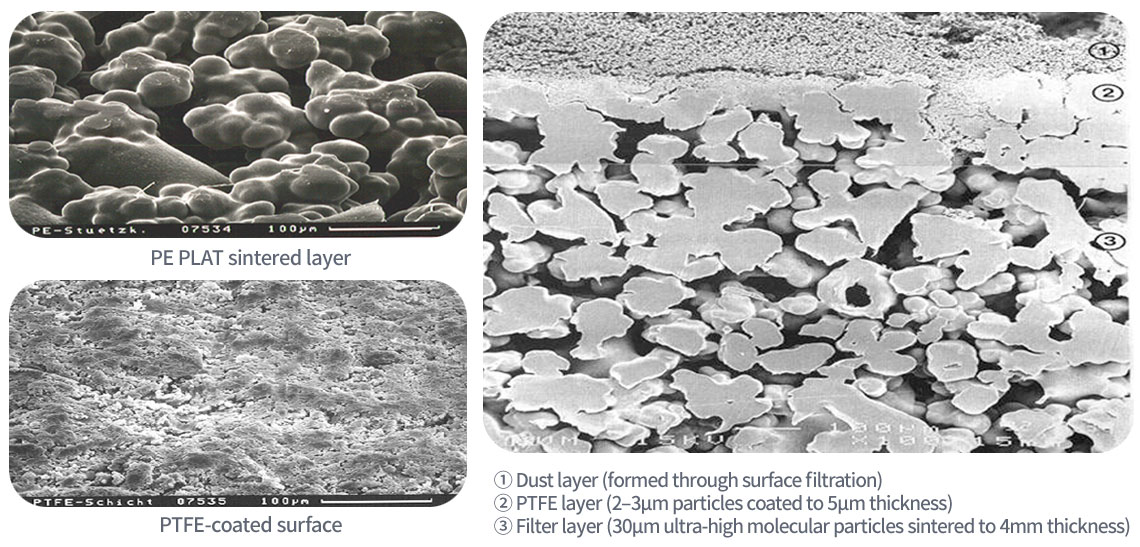

The PTFE-coated surface provides excellent water repellency, making it highly effective even in high-humidity conditions.

Its excellent antistatic properties allow safe use even in explosive gas environments.

Its corrosion- and wear-resistant frame addresses the durability issues seen in conventional dust collectors.

As a result, regular maintenance is unnecessary. The PTFE-coated surface prevents dust accumulation and enables efficient release, ensuring stable pressure and long-term performance.

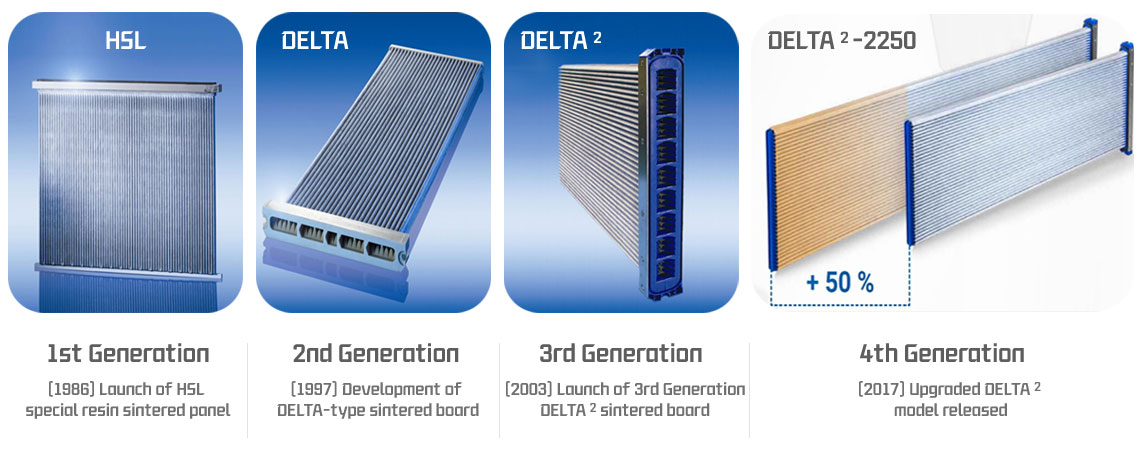

4th Generation High-Efficiency Model

Differential pressure characteristics of special resin sintered filters

Performance of dust collectors using special resin sintered filters

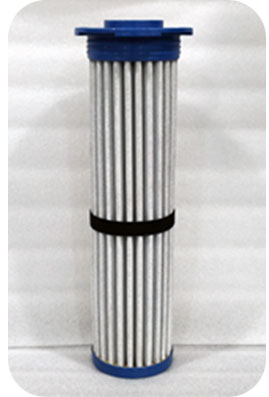

Special Resin Sintered Filter

Why Choose a Special Resin Sintered Filter?

▪️ Provides 3 times the filtration area compared to conventional filters, enabling expansion in confined spaces or within existing dust collectors.

▪️ The PTFE coating prevents pressure buildup, enhancing operational efficiency.

▪️ Constructed by sintering ultra-high molecular weight PE blends, the filter remains dimensionally stable during cleaning, maintaining long-term performance and lasting over 10 times longer than standard filters.

▪️ Suitable for processes with high moisture and oil content, thanks to the PTFE coating.

▪️ Its excellent chemical resistance makes it suitable for a wide range of industrial environments.

▪️ Its rigid design eliminates the need for filter cages and prevents clogging—common in pleated bag filters—allowing for triple the filtration area in the same footprint.

▪️ The filter has been proven over a decade of use in major Chinese steelworks—including Baogang, Hebei, Anben, Wuhan, Xiaogang, and Shandong—and is now widely adopted in new plants.

Benefits of Using Special Resin Sintered Filters

▪️ Expands filtration area in existing systems; reduces installation space for new setups.

▪️ No pressure rise, resulting in reduced fan power consumption.

▪️ Superior cleaning performance reduces compressed air usage.

▪️ No deformation during cleaning, ensuring long service life and cost savings.

▪️ Suitable for processes with high moisture, oil, and chemical content, thanks to the PTFE coating.

Comparative Analysis: EP Dust Collector vs. Sintered Plate Dust Collector

Advantages of UHMW-PE Sintered Filters

Why Choose a Special Resin Sintered Filter?

▪️ Provides three times the filtration area compared to conventional filters, enabling expansion in confined spaces or within existing dust collectors—while also reducing fan energy consumption.

▪ The PTFE coating prevents pressure buildup, enhancing operational efficiency.

▪ Constructed by sintering ultra-high molecular weight PE blends, the filter remains dimensionally stable during cleaning, maintaining long-term performance and lasting over 15 times longer than standard filters.

▪ The PTFE layer also enables use in processes with high moisture or oil content.

▪ Its excellent chemical resistance makes it suitable for a wide range of industrial environments.

▪ Its rigid design eliminates the need for filter cages and prevents clogging common in pleated bag filters allowing for triple the filtration area in the same footprint.

▪ The filter has been proven over a decade of use in major Chinese steelworks including Baogang, Hebei, Anben, Wuhan, Xiaogang, and Shandong and is now widely adopted in new plants.

Benefits of Using Special Resin Sintered Filters

▪️ Unlike Nomex filters used in hot-rolling processes, which require annual replacement, sintered filters do not require replacement.

▪ Although sintered filters cost 4 to 5 times more, the cost of five Nomex replacements covers one sintered filter—with no additional maintenance.

▪ Expands filtration area in existing systems; reduces installation space for new setups

▪ No pressure rise, resulting in reduced fan power consumption.

▪ Superior cleaning performance reduces compressed air usage.

▪ No shrinkage or expansion during cleaning ensures a long (15-year) lifespan and high cost efficiency.

▪ Suitable for processes with high moisture, oil, and chemical content, thanks to the PTFE coating.

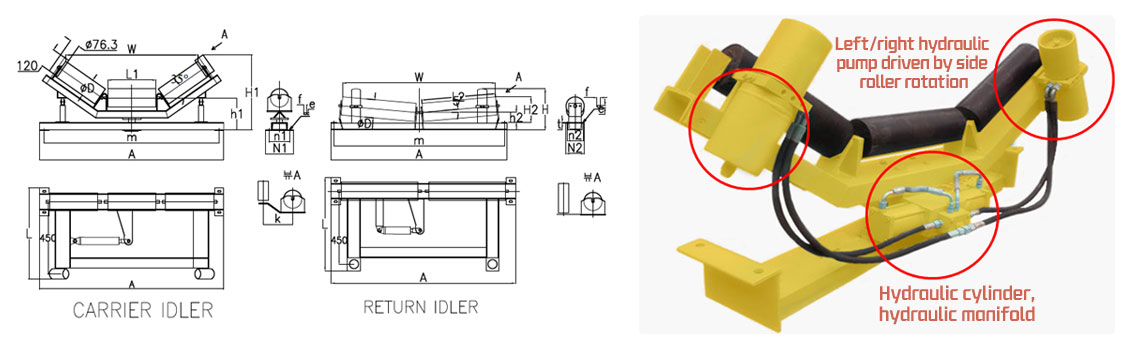

Powerless Model : VAC/VAR-900W~2200W & CUSTOMIZER

Applications

Steel works/power plant/mine transportation/cement manufacturing/Wharf/mineral transportation/Transportation of coal,

iron ore, & subsidiary materials

Product feature

Automatic alignment devices for conveyor belts are typically installed in facilities such as steel mills, power plants, and cement plants to correct belt misalignment during operation. The core feature of the Non-Powered B/C Automatic Alignment Device is its ability to use rotational friction caused by belt misalignment to activate a hydraulic pump—without any external power source. This induces linear motion in the hydraulic cylinder, which rotates the center axis of the carrier or return roller to realign the belt automatically.

Product line-up