A Growing Company with Customers

Through differentiated technology and excellent services,

we will be a best company that develops with our customers by contributing to create customer value.

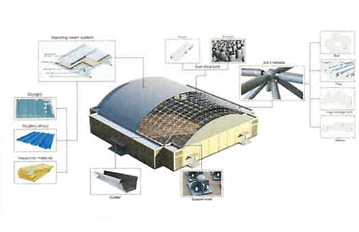

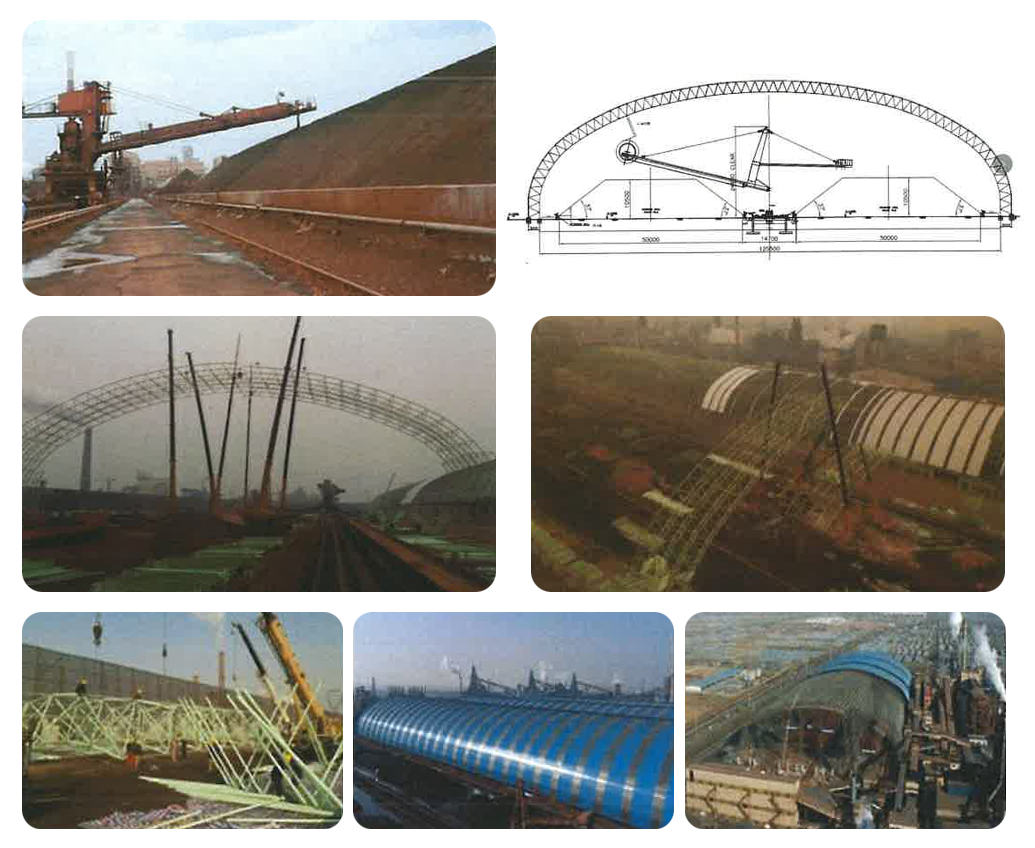

Yard Sealing Application

| Surface Treatment Specifications | Hot-dip galvanizing |

| Corrosion protection | Cathodic & barrier |

| Edge and corner protection | Uniform coverage including corners, edges, and threads |

| Coating thickness | 1.7 to 3.4 mils |

| Bond Strength | 3,600psi |

| Material hardness | Alloy layer harder than base steel (DPN 179–250) |

| Operating temperature | -100 C to 200 C |

| Paint ability | Can be painted |

| Application | Factory shop |

| Production environment | Weather-independent manufacturing |

| Final treatment | Chemically cleaned, dipped in molten zinc, and rotated to remove excess coating |

| Guaranteed service life (maintenance cycle) | Over 50 years |

| Suitability | Suitable for all-weather indoor/outdoor construction |